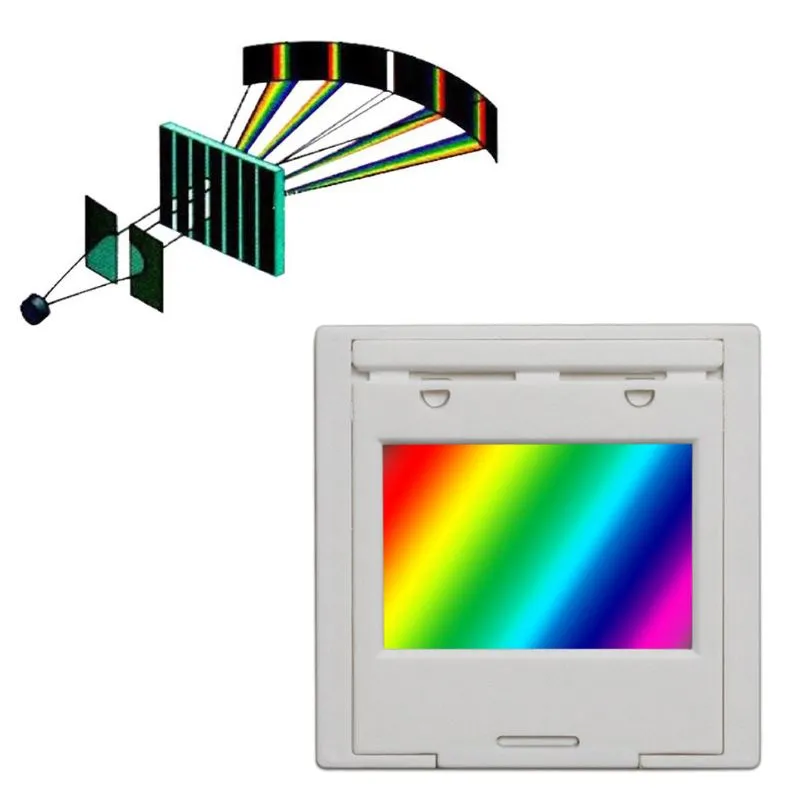

Monochromators use concave or plane gratings along with concave mirrors to select a narrow wavelength band out of incident light. Gratings are used in a wide variety of different applications, but common systems include: Monochromators This can be useful for reducing the total number of optical components needed in a system, but the focal properties of the system will be wavelength-dependent. Concave gratings are curved and therefore either converge or diverge light. Plane gratings also generally reduce system complexity compared to concave gratings. This is beneficial in many applications because the focal properties of the system are wavelength independent. If their grooves are straight and equally spaced, the grating is flat, and incident light is collimated, all of the diffracted light will be collimated. Plane gratings are flat and much more common. Concave GratingsĪll of the above grating types can again be broken down into plane (or plano-) and concave gratings, which describes their overall shape. These gratings are ideal for situations where high resolution is needed, such as sensitive astronomical instruments and systems striving for atomic resolution. Illuminating an Echelle grating at a high angle of incidence ( α) will result in high dispersion, resolving power, and efficiency with a low dependence on polarization. Echelle GratingsĮchelle gratings feature a higher groove spacing, or lower groove density, than other gratings, typically by around a factor of 10 but sometimes as high as a factor of 100. Ruled gratings typically have triangular grooves, such as those shown in Figure 1, while holographic gratings generally have sinusoidal grooves, ( Figures 3 and 4).įigure 4: Holographic diffraction gratings typically feature sinusoidal grooves. Chemicals are then used to remove remaining photoresist, leaving behind a grating pattern. In holographic gratings, a light-sensitive material called photoresist is deposited onto the substrate and exposed to an optical interference pattern which interacts with the photoresist. The grooves in ruled gratings are mechanically scribed, or cut, into the part, while the grooves in holographic gratings are optically introduced. Holographic Gratingsīoth reflection and transmission gratings can be further broken down into ruled or holographic gratings, which differ in the way that the groove profile is created. Reflection gratings are also commonly known as reflective gratings and transmission gratings are also known as transmissive gratings. Transmission gratings are like lenses with microscopic grooves, and all diffracted orders transmit through the grating but are offset by angles following Equation 1. All diffracted orders reflect off of the grating at different angles. Figures 1 and 2 show reflection gratings, which are essentially mirrors with microscopic grooves.

The two broadest categories of diffraction gratings are reflection and transmission gratings. Therefore, a grating should always be underfilled to prevent stray light from bouncing around the system and creating false signals. Gratings should be at least as large as the incident light cone or beam, or else light from the edges will be lost.

Efficiency curves may also be useful for verifying the level of diffraction across all wavelengths that will be used in the application. There are often so many grooves under illumination that the entrance and exit slits are the limiting factors for system resolution, not the grating.

0 kommentar(er)

0 kommentar(er)